Competing in the global market

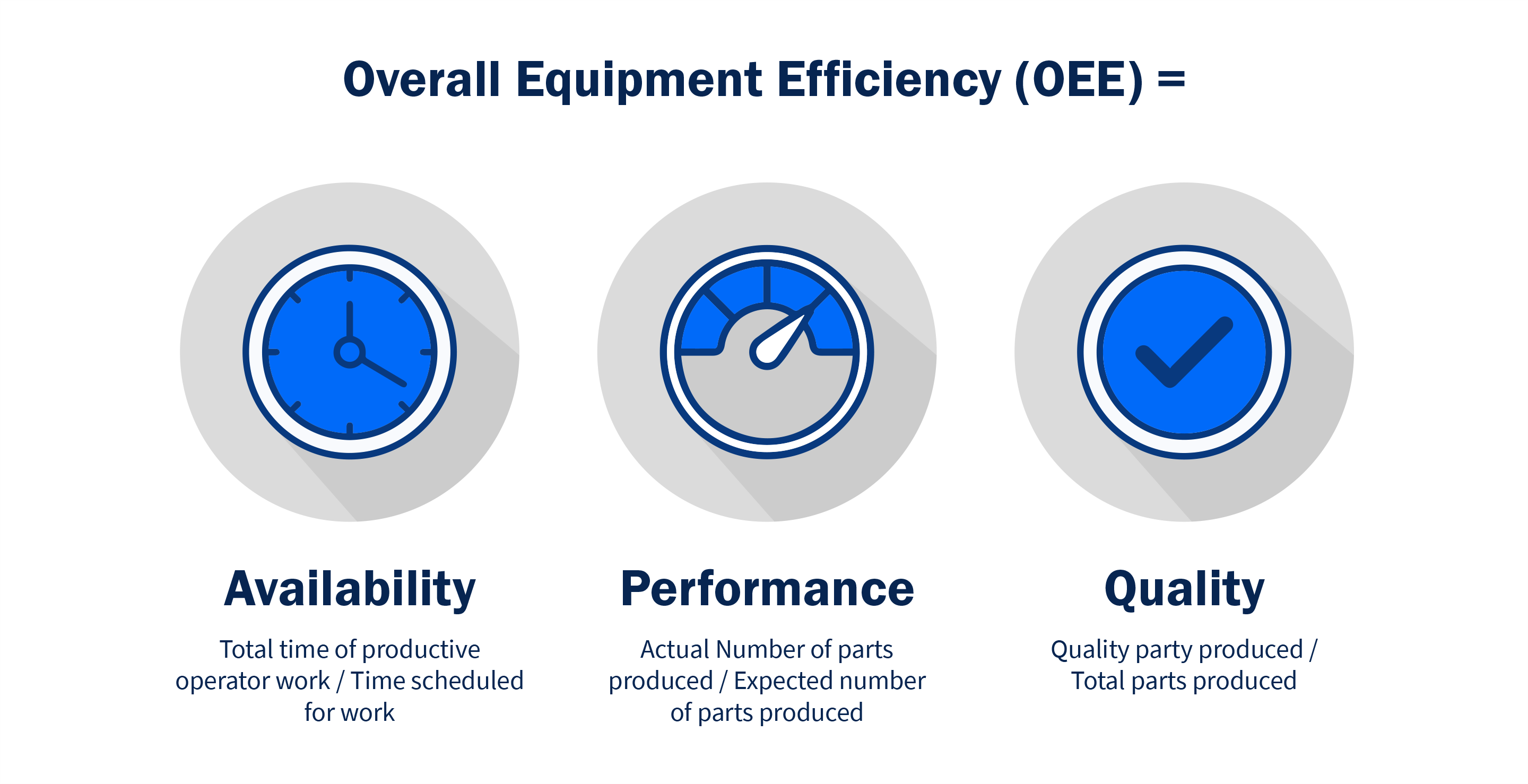

The steel industry has faced challenges related to overcapacity due to recent volatile unpredictable global events, leading to intense price competition. Seeing this trend, our client realized that they weren’t as competitive as they needed to be. They needed to take drastic steps to reduce costs and become more competitive. This prompted them to embark on an Overall Equipment Effectiveness (OEE) journey.