These are difficult times for almost every industry. However, the rising cost of energy and disruption to global supply chains seen in the last few years is making life particularly difficult for many Canadian and American manufacturers.

The COVID epidemic has been a significant factor as well. In 2020 alone, the Canadian manufacturing industry lost over 10% of its workforce due to the COVID-19 pandemic1.

Furthermore, Canada’s manufacturing sector is responsible for a disproportionate fraction of the country’s greenhouse gas emissions, making it a significant contributor to climate change2. The environmental and PR pressure that it produces can make it harder than ever to grow a manufacturing business.

All this only makes it more important for manufacturers to change the way they operate under the ‘new normal’. In order to remain competitive, the Canadian and American manufacturing industries must embrace digital transformation and sustainability. To do that, they’ll need to improve their ability to leverage data and analytics.

The Canadian manufacturing industry has been slow to adopt digital transformation technologies. Barely 16% of manufacturers report a high level of adoption of Industry 4.0 technologies3. With only a fraction of Canada’s manufacturers making good use of digital transformation, Canadian manufacturing productivity has been in decline. Right now, Canada ranks 19th out of 34 countries for productivity growth4.

But that means must of the industry has a great deal to gain, both in terms of competitive advantage and raw profitability. By mapping out the digital transformation of their processes and products, as well as by partnering with the companies who can help them truly leverage the power of transformation, change for the better is within grasp.

I don’t mean a naïve, venturesome investment in an uncertain trend, either. I refer to adopting a proven, well-understood methodology in order to make yourself a key driver in North America’s economic recovery.

One reason Canadian manufacturers have been slow to adopt these methodologies is the way they see themselves. Far too many do not define themselves as ‘advanced manufacturers’ or ‘early adopters’, and thereby limit their ability to compete with larger organizations or those based in traditionally ‘advanced’ regions. However, the beauty of digital transformation is that it is truly egalitarian – it is effective at both large and small scales, and offers advantages to nearly every manufacturer who cares to adapt these methods to their development and production processes.

Here, we’ll explore four key ways big data and analytics technologies can help Canadian and American manufacturers overcome these challenges, improving both the profitability and sustainability of their operations.

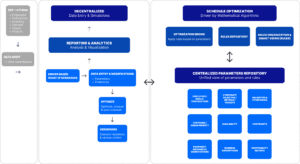

Fig: Reference/Sample optimization Setup

1) Quality Control: Improve product quality and reduce waste.

Quality control and quality assurance play a huge role in digital transformation, and nowhere more than in the manufacturing industry. Nevertheless, it is consistently undervalued.

Traditional QA and QC methodologies are consistent and reliable, as well as slow to adapt to the rapid changes of today’s markets. Technology, demand and customer expectations change by the minute now, not by the year. By leveraging data and analytics solutions, manufacturers can identify quality issues in real-time and take corrective actions to minimize waste and improve efficiency.

That is how those manufacturers who embrace the strengths of more data-driven QA and QC solutions make themselves more agile without compromising quality or reliability, becoming more competitive.

2) Price Forecasting: Optimize pricing strategies and increase profitability.

Price forecasting applications evaluate the characteristics, demanded seasonal trends of a commodity, as well as factors like the price of the commodities needed to create it. In this context, analytics solutions predict the probable price of the commodities, products and services you need to make your own products, allowing you to plan that much farther ahead. You can ride out price spikes and shortages, and prepare to fill those shortages for businesses farther down the supply chain.

The best price forecasting models can also be used to increase the engagement of your customers and the loyalty of your partners. You can choose the optimal time to stock up on key commodities, and thereby offer your products or services at a lower rate than the competition while still turning a tidy profit.

With a truly effective price forecasting analytics application, manufacturers can develop pricing models which optimize both affordability and profitability over the long term. That is how you adapt to the competing demands of volatile commodities markets and rapidly shifting global demand.

3) Predictive Maintenance: Optimize equipment performance and reduce downtime.

Naturally, we want to get the absolute most out of our machines and our people. But we all know that does not mean simply increasing the speed of the assembly line! Just running it at peak efficiency can have dire maintenance consequences. If something does break, the whole line stops, and efficiency tanks.

The digital transformation of predictive maintenance helps you spot the real problems in your process, and helps you develop a consistent approach to mitigating them. This boost in efficiency alone has been enough to make predictive maintenance the industry standard elsewhere in the world.

By leveraging your data more effectively, a predictive maintenance solution can spot the potential for equipment failures before they happen, and help you reduce downtime by scheduling vitally needed corrective actions before the line grinds to a halt. In the final analysis, this increases profitability and efficiency by reducing wasted materials and unproductive labor costs. It even reduces your carbon footprint.

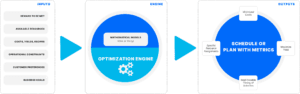

Fig: Schedule optimization for predictive maintenance.

4) Forecasting Sales: Improve production planning and reduce inventory costs.

Digitally transformed sales forecasting means leveraging your data to better estimate future revenue. A sales forecasting analytics solution looks at everything from market trends to patterns in individual customer behaviors to better predict demand in the short, medium and long terms. That lets you plan farther ahead and tailor your production schedules to the expected demand.

Such an application need not make predictions only about your company as a whole. It can also make accurate predictions about the performance of individual sales units, which can feed back into many other aspects of management.

In coming publications, we’ll look at each of these cases in more detail, and give you examples of how we can put these predictive and analytic tools to work for you.

Sources

2: www.canada.ca/en/environment-climate-change